From design and style and machinery import to commissioning and education, we assist you at just about every action from the journey. We've helped builders, builders, and architects provide their visions to existence over the years.

Horizontal AAC Block Machines :- Molds that go horizontally down the generation line can be a function of horizontal machines. They can be routinely utilized in high-quantity manufacturing environments and provide versatility in running distinct block measurements.

Correct processing improves the consistency and top quality in the AAC blocks, lowering materials waste and bettering manufacturing performance.

The reducing part capabilities substantial-precision chopping products that slices the pre-cured blocks into ideal sizes and shapes with minimal wastage.

Autoclave :- The autoclave is usually a higher-pressure steam chamber that cures the Reduce blocks less than controlled ailments. This process enhances the power and longevity of the AAC blocks.

The packing part involves automatic units for stacking, packing, and securing concluded AAC blocks for transport.

Integrates a robust generation administration procedure which allows true-time checking and Charge of the manufacturing procedure. This system makes sure operational effectiveness, regularity in merchandise high quality, and the opportunity to adapt to different creation needs.

Also referred to as brick-making machines, our AAC Block Making Machines are manufactured with exceptional excellent specifications to ensure longevity and efficiency. Committed to excellence, we offer these superior-efficiency machines at competitive prices, making them an ideal option for companies in the development field.

Highly developed monitoring devices assure the best good quality standards are maintained through the generation course of action. Strong machinery with minimal servicing requirements cuts down downtime and assures continuous operation. Factors Supplied by Brickwell

Brickwell delivers automated programs with the fabrication and circulation of steel mesh, which serves as reinforcement for AAC panels.

Our AAC division continues to be centered on supporting top quality development via Sophisticated and successful manufacturing programs across India.

With about 20 years of expertise, we provide one particular-stop services alternatives that maximize manufacturing effectiveness and capability whilst ensuring long-time period dependability.

Conveyor Programs: These techniques transportation raw components and concluded solutions all over the manufacturing line, making sure effectiveness and decreasing guide labor.

They control each action in the output approach, from packaging to mixing. Large manufacturing services that require substantial output while preserving consistent top quality are the best match for these products.

Chopping Machine:-cutting machines slice it into specific blocks. These machines can carry out both of those vertical and horizontal cuts.

The pouring process is designed for exact and managed filling of molds Using the AAC slurry, when the pre-curing procedure makes certain the combination achieves the ideal consistency and power in advance of additional processing. This area ensures dimensional precision and improves the standard of the ultimate product.

Moulds: Moulds shape the slurry into blocks. They can be custom-made to make different sizes and styles of AAC blocks.

An AAC block making machine is actually a specialized piece of equipment created to make autoclaved aerated concrete blocks. These machines streamline the manufacturing approach by automating several phases for example mixing, pouring, slicing, and curing. The result is really a higher-top quality solution that meets the requires of contemporary construction.

Vertical AAC Block Machines :- Vertical molds that travel through each individual generation phase are used by vertical machines. They are often completely automatic for prime-potential generation and optimize Place efficiency.

Helpful task administration and arranging Dependable machines supply and logistics Supervised set up for precision and high quality With a strong research and growth team, Innovative output techniques, in addition to a effectively-recognized source chain, Brickwell guarantees extensive and timely remedies for its prospects.

Supplying you the top number of mini aac block manufacturing plant, low expenditure startup aac plant, check here aac updragable alc block plant, smaller aac blocks plant, absolutely computerized aac plant and semi computerized aac block making machine with helpful & well timed supply.

We offer a comprehensive right after-sales support framework to be sure ideal plant functionality and effectiveness. Providers contain:

Given that 2010 Brickwell has helped Developers, Builders, and Architects, change their goals into attractive structures that enhance and boost any location. Brickwell is for the forefront of introducing innovating present day construction solutions and answers to further improve efficiency and profitability.

Plant scheduling and layout Manufacturing and set up Commissioning and personnel education Uncooked material configuration and screening By specializing in elements like manufacturing facility infrastructure, local industry tendencies, and environmental conditions, Brickwell assures a seamless setup system that aligns with particular specialized prerequisites.

Brickwell empowers companies by giving slicing-edge AAC plant methods that fulfill global specifications, paving the best way for the greener and more efficient long term in developing supplies manufacturing.

This guarantees compliance with venture specifications and facilitates efficient use in design initiatives.

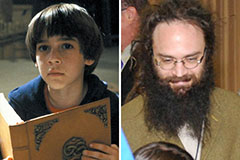

Barret Oliver Then & Now!

Barret Oliver Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!